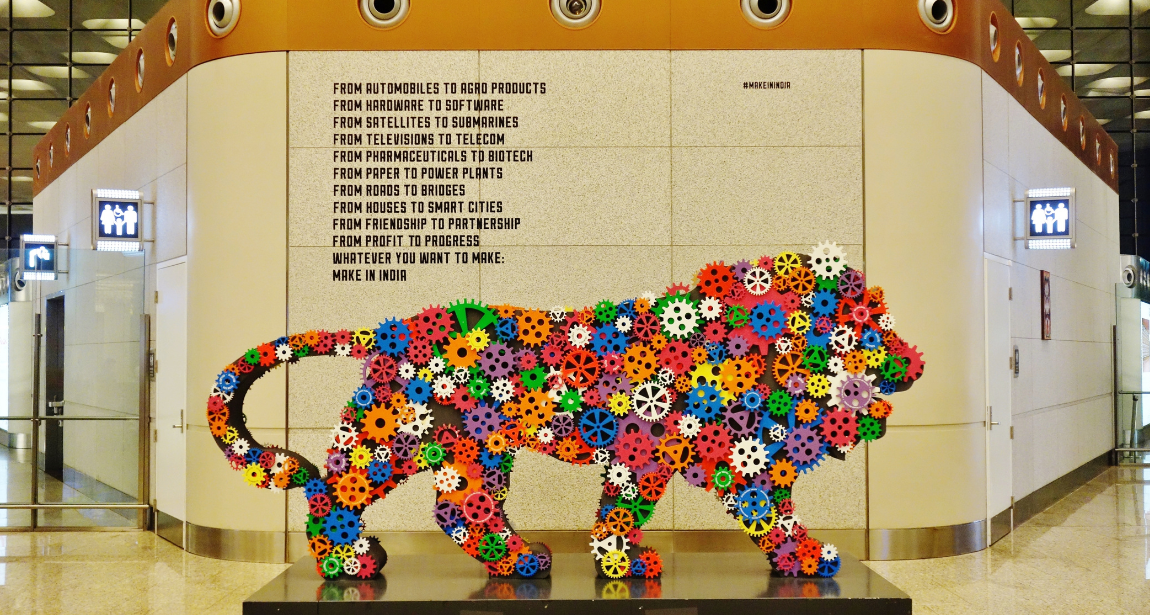

Make in India @10

IN DEPTH

By Anil Padmanabhan

- Cisco opens its first manufacturing plant in Sriperumbudur, Tamil Nadu;

- Adani Group begins production at South Asia’s largest missile complex Kanpur, Uttar Pradesh;

- Apple begins manufacture of Made in India iPhone16;

- Aston Shoes, based out of Tamil Nadu, to manufacture 1 million pairs of a single design sneakers for a US MNC manufacturing shoes.

On the eve of the 10th anniversary of ‘Make in India’, Cisco, the US multinational digital communications technology conglomerate corporation headquartered in San Jose, California, inaugurated its first major manufacturing facility in Chennai.

This may have been a happy coincidence, yet it is also a reflection of the success of the industrial policy strategy launched to integrate India into global supply chains. More importantly, the move by Cisco is not an exception. It is part of an emerging trend, especially as India steadily overcomes legacy deficits in infrastructure and improves ease of doing business—providing an environment conducive to promote entrepreneurship and business.

The listicle shared in the beginning, shows India is steadily expanding its footprint in global supply chains as foreign firms begin to up their investments in India. This, even as domestic firms up their game and acquire global competitivity. Undoubtedly, the ongoing reset to global geopolitics is making India’s task that much easier.

Shortly after the company’s plant was inaugurated in Srimperumbudur, Dave West, President, Asia Pacific, Japan, and Greater China at Cisco, explained the company’s move in a post on the social media platform Linkedin.

“This strategic investment not only contributes to India’s technological growth but also boosts local innovation. It will produce advanced technologies, including a range of Cisco’s best-in-class routing and switching products, to meet the growing technology needs of companies in India and across the world,” he said, before adding, “The investment in this facility over the next several years will boost both exports and domestic production and support India’s growth. This marks the first phase of a multi-year investment projected to generate over $1.3B annually in combined exports and domestic production. The facility is also expected to create 1,200 jobs in the state. Beyond that, it’s another step towards accelerating India’s transition into a leading digital economy.”

To be sure the ‘Make in India’ initiative is still a work in progress and has already seen an iteration with the launch of the Performance Linked Incentive (PLI)—which incentivises companies on incremental sales from products manufactured in India.

With an impressive outlay of Rs 1.97 lakh crore (over $26 billion), PLI, which extends to 14 key sectors, is aimed at fostering investment in cutting-edge technology and promoting global competitiveness—creating domestic champions that can hold their own globally.

As of 30 July, 755 applications have been approved across these sectors, leading to an investment realization of Rs.1.23 lakh crore by March 2024—including becoming one of the global locations for Apple to manufacture the iconic iPhone.

Amitabh Kant, one of the architects of the Make in India initiative and G20 Sherpa, summed it up best. In an interview granted to this newsletter, he said, “Looking ahead, India is well-positioned to create large champions that will drive manufacturing in critical areas. There is a growing realization that we must focus on cutting-edge sectors like artificial intelligence, quantum computing, semiconductors, and green hydrogen. These are areas where the government has launched specific missions, such as the Rs 76,000 crore semiconductor mission and the green hydrogen mission. Never before have we seen a government so strongly focus on future technologies.”

First Principles

Ten years ago, doing business in India was a challenge. The country was still working its way out of the era of Licence Raj. As a result, red tape, high cost of capital and an out-of-date indirect tax structure, put domestic business at a disadvantage vis-à-vis their global counterparts.

The Make in India strategy therefore worked on first principles to enable a conducive environment to improve competitiveness of Indian industry.

The strategy rested on several pillars:

New Processes: It identified ease of doing business as the key to promote entrepreneurship. Several measures were implemented to enhance the business environment, including the rollout of the Goods and Services Tax, the Bankruptcy Code, rationalisation of corporate tax rates and so on–making it more conducive for startups and established enterprises alike.

New Infrastructure: The government focused on developing industrial corridors and smart cities, integrating state-of-the-art technology and high-speed communication to create world-class infrastructure.

Promote Innovation: Streamlining the registration systems and improved intellectual property rights infrastructure, identify skill gaps and develop the workforce accordingly.

Liberalised FDI: Foreign investment was liberalised in sectors including closely protected sectors like defence production, insurance, medical devices, construction, and railways infrastructure.

Mindset Reset: The government embraced the role of a facilitator rather than a regulator, partnering with industry to drive the country’s economic development. Coining the slogan, “Pro-poor and Pro-business”, the government formally enlisted business as an important stakeholder in the Indian economy.

In the final analysis it is clear that the ‘Make in India’ strategy has registered some notable successes. Indeed, India has come a long way since the era of the Licence Raj, which had hobbled the growth of domestic industry. It still has a long way to go. But, as the cliché goes, it is a cup that is half-full.